ACCURATE HEAT TREATMENT

The heat treatment appropriate for the material optimises the physical properties of the forged parts. Using accurately controlled heat treatment, the physical properties meet our customers‘ requirements or standard specifications.

STOOSS operates with environmentally

compatible natural gas and electrically powered heat treatment furnaces which are calibrated regularly.

The parts are quenched in oil, water or polymer.

Up-to-date measurement and control instruments record the specific heat treatments such as normalizing, annealing, tempering or soft annealing appropriate for each material.

Safety and long product life

Forged parts from STOOSS are outstanding because of their:

material selected on the strength of its analysis and degree of purity

exact shaping

ideal degree of forming

optimum grain structure

minimum allowances, narrow tolerances

thermal treatment relevant to the application

Moreover, they offer exceptional advantages:

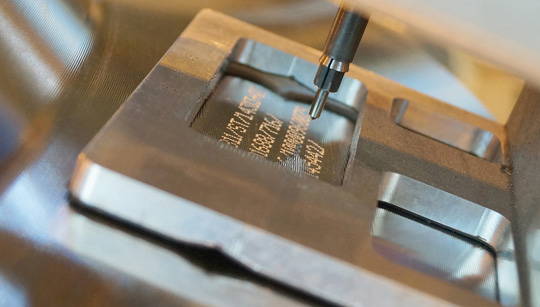

excellent manufacture in respect of surface quality and accuracy of form

suitable for processing on CNC

machines

reduction of mechanical processing time, thus saving costs

high degree of security against fatigue cracks